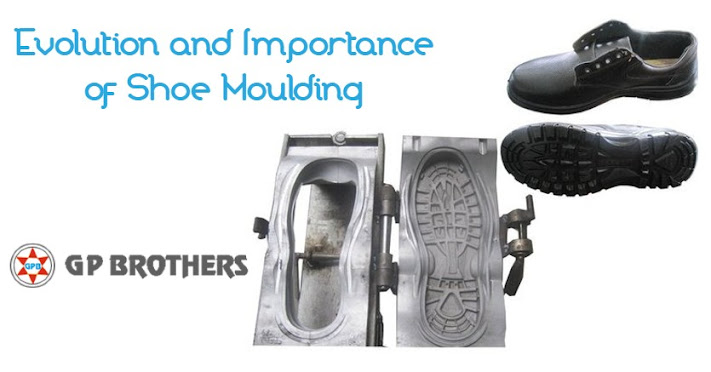

Many shoemakers employ injection moulding to form and join soles to uppers in complete ('all-moulded') footwear or to mould a sole unit on its own – or as a 'direct injection moulding' method to both form and join soles to uppers. Thermoplastics, such as polyvinyl chloride (PVC) and thermoplastic rubber (TR), as well as polyurethane (PU) for reaction injection moulding,' are the only materials capable of injection moulding.

The lid of the shoe mould is formed by the lasted top, and the hole in which the sole forms is formed by the base of the mould. The 'nip line' of the mould must be tightly sealed against the upper in order for the sole material to not seep out excessively.

A ram or screw-type plunger is used in injection moulding to drive molten plastic material into a mould cavity. This cools and hardens into a shape that fits to the mould's contours. It is most typically employed to process thermoplastic polymers, while recent advancements have allowed thermosetting polymers to be moulded as well. Thermoplastics are widely utilised because of features that make them ideal for injection moulding, such as their ease of recycling, versatility (enabling them to be used in a wide range of applications), and ability to soften and flow when heated.

Connecting

During the last quarter-century, injection moulding technology has advanced significantly. In many industries, the moulding machine operator can now detect if his or her work is successful even before the shoe mould is opened (due to computer control and in-mould sensors). The development of all-electric machines has been one of the most significant technological advancements in the world of injection moulding. Modern servo-electric motors only utilise power when they need to move a section of the machine, rather than constantly operating pumps to provide the oil pressure required by earlier hydraulic machines. As a result, while the device is not moving, no electricity is required. In Japan, where environmental rules made it difficult to dispose of leftover hydraulic fluid and high energy prices encouraged the sector to adopt efficiency, all-electrical injection moulding technology was developed.

Shoe moulding and the creation of fully moulded footwear are now widespread. These procedures, on the other hand, have had a long (and in some cases, torturous) road to their established places in the world of shoemaking. What does the future hold for us? Even in the world of moulded footwear, only a fool would claim that everything that could be invented has already been invented.

Injection moulding is becoming increasingly popular in the shoe industry. You've probably worn multiple pairs of shoes created with an injection mould without realising it. The top of the shoe is made of leather or cloth that has been sewed together, while the sole can be made of a variety of materials.

Comfort

Comfort shoes are designed to provide you with a comfortable walking surface, but they are not as sophisticated as you may believe. The outsole, or bottom of the shoe, can be created in a more comfortable pattern for you. Waffle moulds are used by certain companies to make their shoes light, whereas curved moulds are used by others to produce a cushion for your foot.

Also Read :- What Is the Importance of Shoe Molds and Shoe Dies?

Your shoes' arches will not collapse because they were manufactured in an injection mould, and the outsoles will not readily break down because they are all made of the same material. If you choose a shoe with a rubber outsole, it was most likely created with an injection. This procedure naturally increases the shoe's durability, and a forward-thinking corporation can use the mould to improve the shoe's comfort.

The Form

The outsole's shape is also dictated by the mould. You can wear shoes with the corporate logo embossed on them, or you can wear shoes with a curved outsole to make walking easier. You'll notice that each shoe from the same company has the identical outsole, which is due to the injection moulds.

When you find a shoe produced with injection moulding, you can be confident that every other shoe from that firm will feel the same way. This constancy results in a shoe that you can rely on for many years.